1. Smart software platform with user friendly designed system for convenient use.

2. Flexible manufacturing features that support simultaneous manufacturing of multiple orders, styles, and processes.

3. Rich manufacturing data management functions and customization of the manufacturing process.

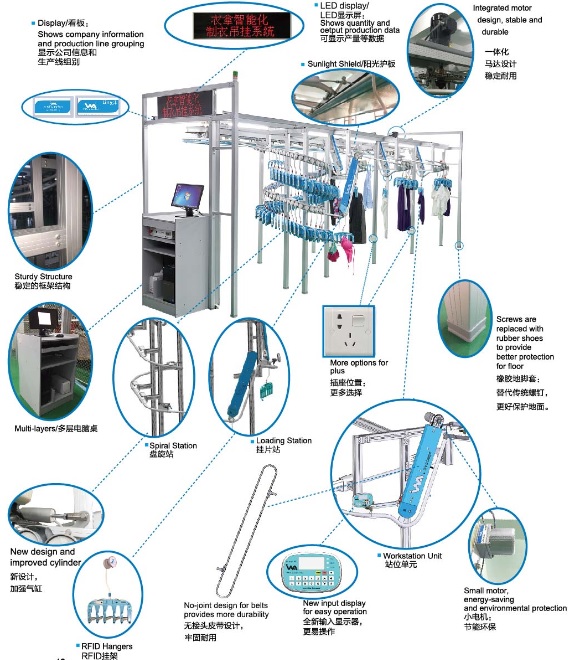

4. Wireless workstation terminal that enables flexible installation and can be adjusted according to operator's standing or sitting position.

5. A smart hanger distribution algorithm can calculate the hanger path according to the real-time status of each station to improve overall efficiency.

6. Workstation terminal that display various information including output, efficiency, and salary according to different styles, operations, colours, sizes and shifts.

7. Quality management module that enables customize quality control, detailed quality statistics report and traceability analysis.

8. Smart rework operation that automatically indentify the right employess for touch-up on repair.

9. Workstation supports hot-swapping of style, color, size, etc., bringing operation convenience and improving sewing efficiency.

10. Smart hanger flow analysis, smart prediction of production potential, and bottleneck warning.

11. Production monitoring function that monitors real-time information of each workstation through software.

12. Production line display that shows rich production analysis and statistical charts.

13. A variety of data interface that connect with production management software, such as MES and ERP for real-time data docking.

14. Supports seamless connection with client's production tablet via tablet interfaces.